|

| | PPG Wave / EVU MIDI Retrofit

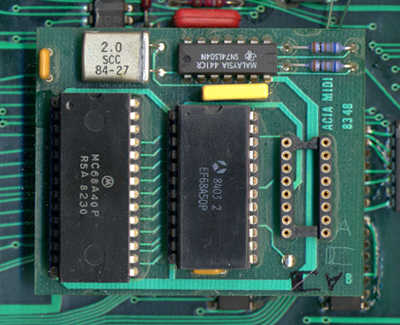

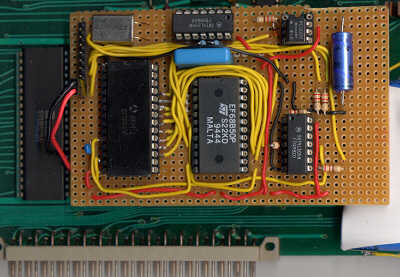

All PPG devices built before 1984 came without a MIDI interface. This is the

case for many of the Waves of type 2.2 and for early EVUs.

When the Wave 2.3 appeared, you had the possibility to upgrade an existing

Wave 2.2 to 2.3. Two of these upgraded Waves are in my possession. During this

upgrade, 8 single outs and MIDI was added, too. The MIDI retrofit consists of a

small add-on board that is plugged into the I/O-82 board:

The 6840

chip is removed from the I/O-82 board and plugged into the ACIA MIDI

board. The ACIA MIDI Board is then plugged into the original 6840 socket,

after having been soldered to the I/O- 82 board in two places (not visible

on this picture since it's below the add-on board). The 6840

chip is removed from the I/O-82 board and plugged into the ACIA MIDI

board. The ACIA MIDI Board is then plugged into the original 6840 socket,

after having been soldered to the I/O- 82 board in two places (not visible

on this picture since it's below the add-on board).In my case, the

upgrade has been done by PPG directly and (unfortunately) they adhered to

the recommendation to solder it to the original 6840 socket in some places

to guarantee a greater stability... which didn't exactly ease my analysis

of the board.

|

Using the free socket visible in the picture above, the ACIA MIDI board

is then connected to the I/O MIDI board:

The right

one of the two flat cables leads to the ACIA MIDI board (or, on younger

devices that already come with MIDI, to the I/O-84 board), the left one is

for the single outs and is connected to the motherboard. The right

one of the two flat cables leads to the ACIA MIDI board (or, on younger

devices that already come with MIDI, to the I/O-84 board), the left one is

for the single outs and is connected to the motherboard. |

On this (I/O-84 compatible) solution, the MIDI interface is spread

across two boards and inseparably combined with the single outs. To add it to an

unMIDIfied EVU this is unusable, since it already has the single outs on the

front side.

Apart from that, you can't buy the upgrade any more...

Alternative Solution

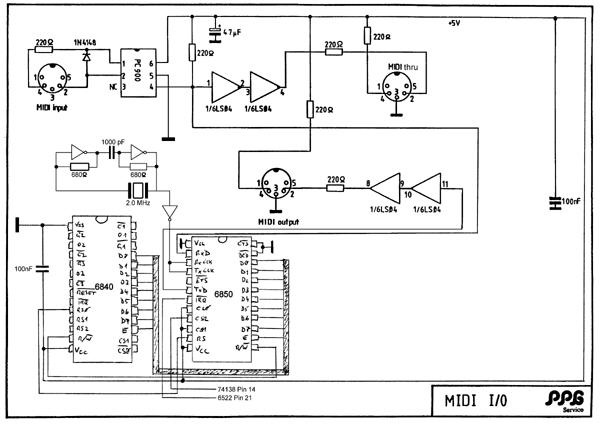

To add MIDI to my EVU, I had to go another way. This consisted of a

functional rebuild of the PPG solution. The first step was to reverse-engineer

it and to work out the schematic behind the logic spread across the two boards.

This lead to the following diagram:

Click here for a big .tif picture in original size or click here for a slightly smaller .gif picture

If somebody finds this familiar, no wonder - one half of that is from

the Wave 2.3 Service Manual.

List Of Needed Materials

| 4 IC sockets DIL 2x14 17,7mm

(3 if different construction - see "Construction Details" below) |

| 1 IC socket DIL 2x12 17,7mm |

| 2 IC sockets DIL 2x7 10,1mm |

| 1 IC socket DIL 2x4 10,1mm

(actually, a socket with 2x3 pins would be needed for the PC900, but I

couldn't find one) |

| 1 6850 ACIA |

| 1 optocoupler PC900 |

| 1 quartz 2.000MHz |

| 1 capacitor 1000pF |

| 2 74LS04 (or 74S04, 74HC04) |

| 1 elco 47µF |

| 1 diode |

| 6 resistors 220 Ohm |

| 2 resistors 680 Ohm |

| 2 (4) capacitors 100nF

depends on the construction - for the7404 chips, I've used sockets with

built-in capacitors (less soldering; see following picture) |

| 3 DIN sockets type 4 (for MIDI) |

| connection cables in matching length; 2x 3 poles (Thru, Out), 1x 2 poles

(In) |

| 1 strip board (mine's roughly 100x160mm, but depending on your skills, it

might even be smaller) |

The following parts are only needed if my "plug-in" solution is

rebuilt:

| 1 male header 2.54mm 10 pins |

| 1 female header 2.54mm 2 contacts

(connection to I/O 82) |

| 1 female header 2.54mm 8 contacts

(connection to the MIDI DIN sockets)

I used prefabricated cables for that - costs more, but needs less soldering. |

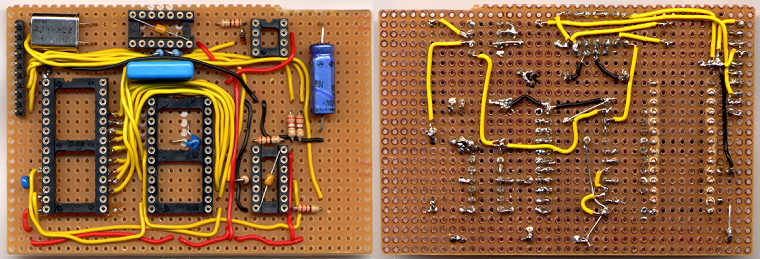

Construction

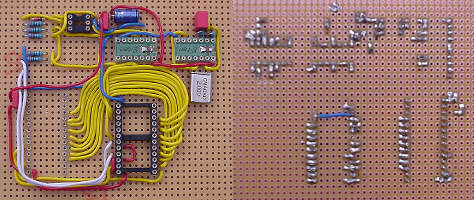

So - then I built it on a 2.54mm strip board. Here's a picture:

Maybe not the best possible work, but my most ambitious soldering project

till now :-)

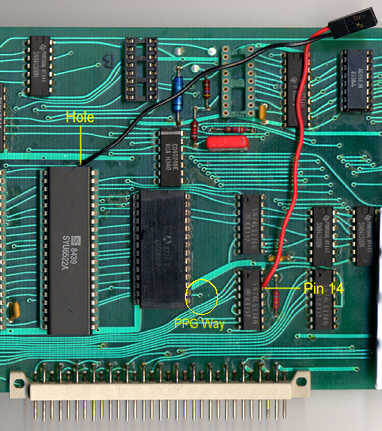

I've done the connection to the I/O- 82 board like that:

The

PPG solution consists of a soldered connection. I prefer solutions that

can be taken apart if necessary and used 2 pins of the male header for

that. The

PPG solution consists of a soldered connection. I prefer solutions that

can be taken apart if necessary and used 2 pins of the male header for

that.

The red cable is directly soldered to pin 14 of the 74LS138. The black

cable is soldered to a hole in the I/O-82 board that's connected to pin 21

of the 6522 (on the soldering side).

PPG had another, functionally equivalent solution: here, an isolated

wire goes through the hole titled "PPG Way" in the

picture on the left and is soldered directly to pin 21 of the 6522 socket. |

|

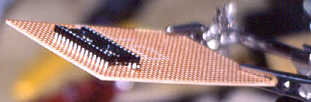

And that's how it looks like when it's complete:

The 8

pins that aren't connected on this picture are used for the MIDI

connections: In (2 pins), Thru (3 pins), Out (3 pins). I didn't want to

put the whole EVU into my scanner :-) The 8

pins that aren't connected on this picture are used for the MIDI

connections: In (2 pins), Thru (3 pins), Out (3 pins). I didn't want to

put the whole EVU into my scanner :-)

I

used DIN sockets of this type: I

used DIN sockets of this type:

Paul Maddox recommended against using this type since the metal

shielding might introduce "hum and strange MIDI data" on MIDI In

if an improper MIDI cable is used, it's better to use plastic sockets.

|

Construction Details

An interesting question, especially for non-electronic engineers like me, was

how the base construction was done which connected the MIDI board to the 6840

socket. If you simply solder a normal IC socket to the board, the pins don't

stick out far enough to be plugged into the original socket... I've worked my

way through some catalogues hoping to find a solution to that problem, but

couldn't find anything. Well, there's always a way - I purposely destroyed a

normal IC socket to use the single pins in there.

With a hot air gun, this went

quite well - after some time, the socket begins to melt (attention: at

this temperature you can burn wood, so be careful!) and I could extract the pins

with an isolated plier. With a hot air gun, this went

quite well - after some time, the socket begins to melt (attention: at

this temperature you can burn wood, so be careful!) and I could extract the pins

with an isolated plier. |

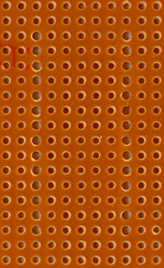

The

next step was a bit easier - the pins have to be submerged in the board so

that they come out far enough to be plugged into the original socket. To

do that, I've carefully widened the necessary 2x14 holes on the board to

1.5mm (see picture on the right). The

next step was a bit easier - the pins have to be submerged in the board so

that they come out far enough to be plugged into the original socket. To

do that, I've carefully widened the necessary 2x14 holes on the board to

1.5mm (see picture on the right). In

these holes, you can easily insert the pins. In

these holes, you can easily insert the pins.

Attention: when soldering the pins to the board, you should use

just the absolute minimum of soldering lead, since the pins have to be

inserted into the socket below them! |

After that a normal socket is put on top of the

single pins. I did it before

soldering - eases the pin alignment a lot. After that a normal socket is put on top of the

single pins. I did it before

soldering - eases the pin alignment a lot.

|

In

theory, using a WireWrap socket instead of the tinkering above should work quite well; a construction of

that kind, however, should be soldered to the socket below, since the pins

stand out about 1cm on the lower side of the board, reducing the

mechanical stability. Alternatively, you could shorten the pins to the

same length, but that means precision work. In

theory, using a WireWrap socket instead of the tinkering above should work quite well; a construction of

that kind, however, should be soldered to the socket below, since the pins

stand out about 1cm on the lower side of the board, reducing the

mechanical stability. Alternatively, you could shorten the pins to the

same length, but that means precision work. |

| If somebody knows a better solution or has a link to existing parts

that don't need such a hassle, please let

me know the details! |

A

very interesting questions in case of my strip board assembly was how to

solder cables to these pins - this has to be done on the upper side, since

there's no space on the soldering side, this needs to stay free to be

plugged into the socket below. To ensure a stable connection, I've used

specially bended cables and additionally soldered them to the board. This

may be absolute overkill since there should be no mechanical stress on

them, but you never know... A

very interesting questions in case of my strip board assembly was how to

solder cables to these pins - this has to be done on the upper side, since

there's no space on the soldering side, this needs to stay free to be

plugged into the socket below. To ensure a stable connection, I've used

specially bended cables and additionally soldered them to the board. This

may be absolute overkill since there should be no mechanical stress on

them, but you never know... |

The

whole thing is then plugged into 2 IC sockets, so that it reaches a height

where it can be put on top of the I/O-82 board without touching the ICs

below it. The

whole thing is then plugged into 2 IC sockets, so that it reaches a height

where it can be put on top of the I/O-82 board without touching the ICs

below it.

PPG, by the way, used the same construction. On the original, the

sockets were soldered together at some places to increase stability. |

Usage

OK... that's it. Nearly.... of course, you've got to drill matching holes in

the back plate of the device. Insert the MIDI sockets there, re-assemble the

thing, and off we go...

Or so.

The Waves and EVUs need a new operating system that knows about the MIDI

interface. For the Wave 2.2, this is at least V4.5, for the EVU it's V3. Images

of the necessary EPROMs are available on Paul Maddox' PPG

CD-ROM (Wave V6 only; Wave V4.5 will be on CD-ROM V3).

If you can't burn EPROMs yourself, you can contact

me.

A completely new version of

the operating system that allows exchange of program data with your computer can

be found here.

Before inserting the new EPROMs, you absolutely have to save the

current programs! Depending on the OS version installed before, chances are very

high that the new program data use a different format, which renders the old

program information absolutely useless.

So... if all went well, the device speaks MIDI as soon as you turn it on the

next time.

Costs for the above solution: about 20 Euro (tools not included).

Time needed: well... it took me about a week, reproduction should be faster.

Others' Solutions

Others' Solutions

Lars Johansson has done the MIDI Interface. Here's his (not yet completed) design:

As you can see, he invested a LOT of time into an optimal placing of the

elements! And here's the finished product:

|

Last update: 10/26/03 |

|

|